People often regard product packaging as something insignificant—simply a box used to wrap a product. However, this is not the case. Outer packaging serves as a direct medium through which companies present their brand image to consumers. It also conveys product functions and features, making packaging an important channel for delivering product information and increasing brand visibility.

The appearance and texture of a packaging box play an important role in attracting consumers. Many consumers assess product quality and brand credibility based on the look and feel of the outer packaging. A well-made box can enhance perceived value, while inadequate packaging may negatively influence purchasing decisions.

During traditional festivals, products with festive characteristics become more prominent in both physical stores and online platforms. Taking the Dragon Boat Festival and the Mid-Autumn Festival as examples, packaging for products such as mooncakes and rice dumplings often incorporates festival-themed patterns and designs. These elements reflect traditional cultural symbols while also highlighting the artistic aspects of packaging design, contributing to visual appeal and consumer interest.

The design of gift box packaging not only shapes visual identity but also conveys cultural meaning. Through appropriate design and structure, packaging can integrate artistic expression with traditional cultural elements, becoming a carrier of cultural value.

From October onward, demand for festive products increases due to holidays such as Double Eleven, New Year’s Day, and the Spring Festival. As seasonal goods enter the market, packaging boxes are often the first element noticed by consumers. To differentiate their products, brands place greater emphasis on packaging design and presentation.

The overall quality of a packaging box depends not only on printed graphics and visual design, but also on the box-making process itself. Reliable box-making equipment plays an important role in determining the texture and structural integrity of the finished box.

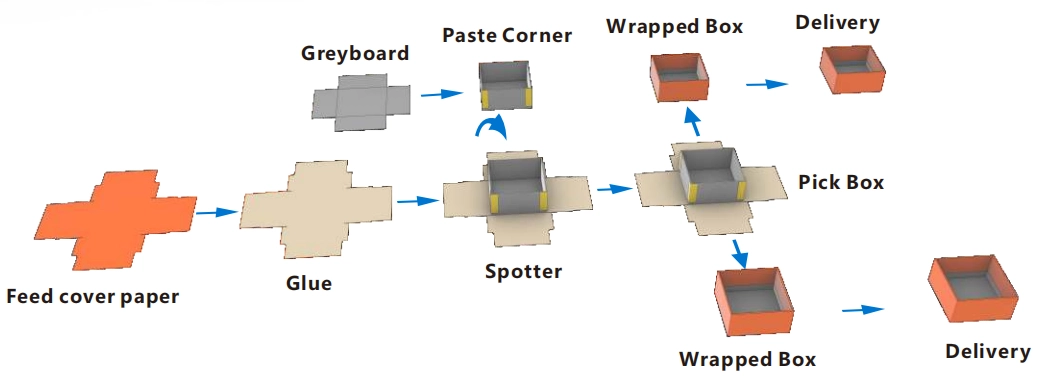

In rigid box production, the manufacturing process is particularly important. The primary materials include wrapping paper and greyboard. Paper materials typically undergo processes such as die cutting and lamination, while greyboard is processed through die cutting or slotting. Subsequent steps include gluing, corner pasting, positioning, and forming. These processes can be completed through fully automated operations, supporting consistent quality and stable production.

The HM-DS3046 automatic rigid box machine series is designed for the production of premium rigid boxes in regular sizes. It features a dual-station, fully automatic intelligent box-making structure suitable for high-speed mass production.

This machine is applicable to the production of various rigid box types, including high-end jewelry boxes, mobile phone boxes, gift boxes, cosmetic boxes, and watch boxes. With a wide box-making range, it is able to meet the requirements of the modern packaging market. The overall machine structure has been newly designed, focusing on improved safety and a refined appearance.

The machine adopts a servo control system combined with an image positioning system, enabling automatic completion of paper feeding, gluing, greyboard feeding, four-corner pasting, positioning, box clamping, edge wrapping, ear folding, and final forming.

Famous-brand servo drives are used in the feeder, gluing unit, and main conveyor, allowing stepless speed adjustment, high precision, and convenient setup, helping to save adjustment time.

The positioning section is equipped with an image positioning system and robotic gripping components, improving positioning accuracy and operational efficiency, with a positioning tolerance of ±0.05 mm and stable operating speed.

The forming unit adopts high-precision silent linear guides and a virtual electronic cam drive, ensuring stable and smooth operation. It also supports a wider range of folding depth and ear folding length, contributing to consistent forming quality.

Key Features & Standard Configuration

- Suit to all kinds of rigid boxes in mass production;

- Parameters adopts computer digital setting;

- Auto error stop and display;

- Automatic feed paper and greyboard;

- 24-hour glue timing heating function;

- Wrapper can input 300 product formulas;

- Corner pasting part with independent man-machine control and heating system;

- Spotter by camera tracing system and SCARA (Selective Compliance Assembly Robot Arm);

- Wrapper can automatic lift and wrap box;

- Automatic control system for glue viscosity (optional);

- Digital setting with memory system (optional);

- The long side and short side are layered and formed;

- Main Slider and pull mold section synchronized;

- Bottom mould use Piston type;

- The box-out direction is parallel to the main conveyor belt.