Features and function:

|

Model |

HM-DC6600 |

HM-DC6610 |

HM-DC6615 |

|

|

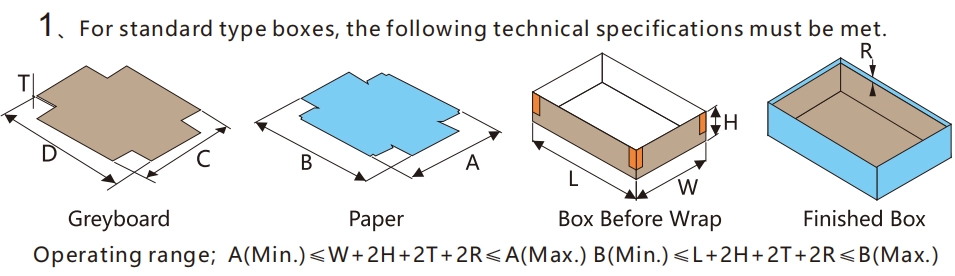

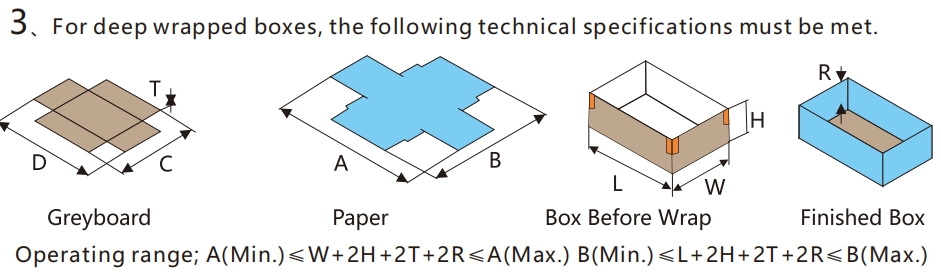

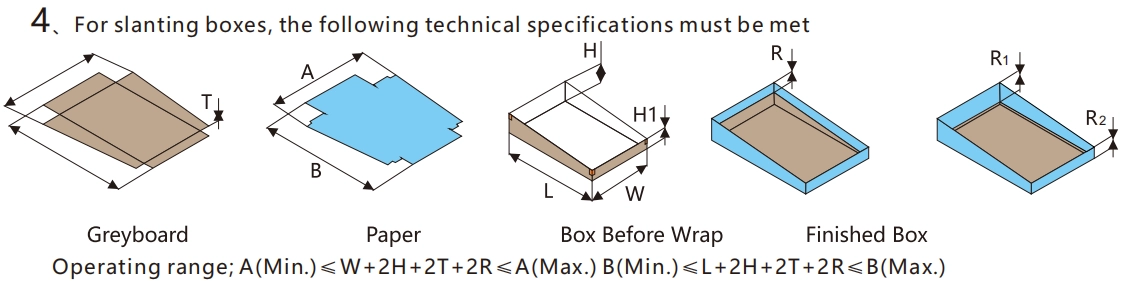

Grey board Size D=Length, C=Width |

Width (Max.) |

420mm |

600mm |

660mm |

|

Width(Min.) |

60mm |

84mm |

124mm |

|

|

Length(Max.) |

420mm |

500mm |

560mm |

|

|

Length (Min.) |

50mm |

74mm |

84mm |

|

|

Thickness T |

1-3mm |

1-3mm |

1-3mm |

|

|

Paper Size B=Length, A=Width |

Length (Max.) B |

460mm |

640mm |

700mm |

|

Length (Min.) B |

95mm |

180mm |

180mm |

|

|

Width (Max) A1 |

460mm |

540mm |

600mm |

|

|

Width (Max) A2 |

380mm |

460mm |

520mm |

|

|

Width(Min.) A |

60mm |

90mm |

95mm |

|

|

Thickness |

80-160gsm |

80-160gsm |

80-160gsm |

|

|

Paper Corner Edge |

E |

10-90mm |

10-90mm |

10-90mm |

|

Finished Box Size |

L(Max.) |

300mm |

400mm |

600mm |

|

L(Min.) |

40mm |

60mm |

100mm |

|

|

W(Max.) |

300mm |

300mm |

400mm |

|

|

W(Min.) |

25mm |

50mm |

50mm |

|

|

H(Max.) |

120mm |

140mm |

150mm |

|

|

H(Min.) |

10mm |

12mm |

12mm |

|

|

Die Stoke |

10-80mm |

10-80mm |

10-80mm |

|

|

Paper Stacker High Max. |

750mm |

750mm |

750mm |

|

|

reyboard Stacker High Max. |

850mm |

850mm |

850mm |

|

|

Glue Tank Volume |

35L |

35L |

35L |

|

|

Air Supply |

460L/min, 0.8MPa |

460L/min, 0.8MPa |

460L/min, 0.8MPa |

|

|

Speed |

≤60pcs/min |

≤60pcs/min |

≤60pcs/min |

|

|

Power/Voltage |

58kW/AC380V |

60kW/AC380V |

64kW/AC380V |

|

|

Power Consumption |

14kW/h |

15kW/h |

16kW/h |

|

|

Net Weight |

8400kg |

8700kg |

9000kg |

|

|

Machine Dimension |

9200 x 5500 x 3000mm |

9600 x 5700 x 3300mm |

9200x5500x3300mm |

|

Remark: